Garage Floor Coating Services

CertaPro Painters® of Indianapolis

Epoxy Garage Floor Coating Services in Indianapolis

CertaPro Painters® of Indianapolis offers specialized epoxy floor coating services for concrete floors in the greater Indianapolis service area. Floor coatings are most commonly applied to residential garage floors, but the coating will work well on all types of concrete floors including basements, patios, walkways, and outdoor stairways. We have a pricing guide with ballpark pricing information for garage floor projects, set up an estimate appointment to get accurate pricing for your project. Watch the video below to learn more about our floor coating services.

The Epoxy Floor Coating Process

Epoxy garage floor installations are usually 2 day projects, starting with a day of diamond grinding, crack repairs, application of moisture barrier, base coat application, then finally we broadcast the flakes into the base coat. On the 2nd day once the epoxy has hardened we scrape the loose flakes, vacuum, then apply two polyaspartic clear coats including an anti-slip additive to create grip.

Diamond Grinding

The diamond grinding process is essential to create the necessary profile into the concrete for adhesion. This is also necessary to remove previous coatings.

Crack & Pit Repair

During the grinding process we will use a hardening crack filler to repair cracks and imperfections to allow of a smooth finish

Moisture Barrier

A moisture barriers is applied to help seal the concrete and increase the strength of the chemical bond in the epoxy base coat

Base Epoxy Coat

The base coat of epoxy is applied evenly and at the appropriate film thickness to allow chips to properly bond

Full Chip Broadcast

As the polyurea levels we broadcast more than the needed supply of chips into the base coating to ensure full and even coverage and a high build.

Get a Free Epoxy Floor Coating Estimate

Interested in having your garage floor updated with an epoxy floor coating? Get started by setting up a free estimate appointment with our team. Have a representative out for a free estimate or start your remote estimate now by simply uploading photos

Benefits of Epoxy Floor Coatings

There are many benefits to having your garage floor coating with an epoxy finish. A few of the main reasons people have the floors installed include:

- Durability: Epoxy floor coatings can be heavy which allows for more chip adhesion meaning more build and protection.

Affordable: Floor coatings are affordable when compared with other floor options the cost per square foot is very competitive - Stain Resistance: A coated floor will resist stains even from difficult liquids like oil and grease

- Aesthetics: A coated floor has a beautify and attractive finish that give a much better look than concrete

- Low Maintenance: Epoxy floors are easy to clean and require little upkeep once installed

More About Epoxy

Epoxy works very differently than conventional garage floor paints. It is not the same kind of product as garage floor paint, and works very differently. Epoxy is a made of a two part coating that gets mixed together, much like an epoxy glue. The two parts of epoxy usually consist of a a resin part and a hardening part.

The two parts when mixed will activate the compound and it will start to cure and harden. It is a far superior coating to paint for flooring projects, the difference is visually apparent in its high gloss, but there are also non visual differences like much stronger durability.

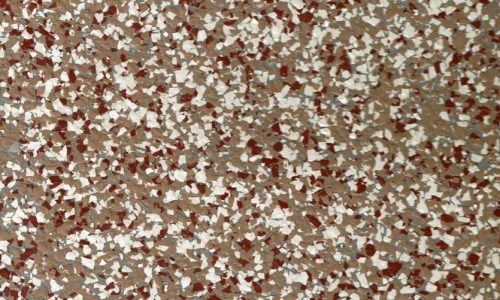

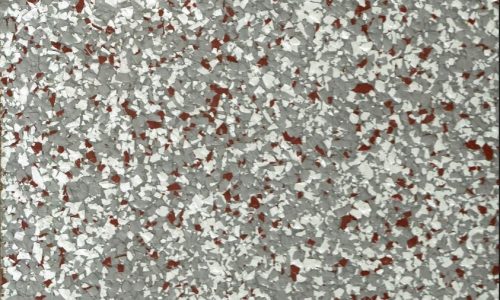

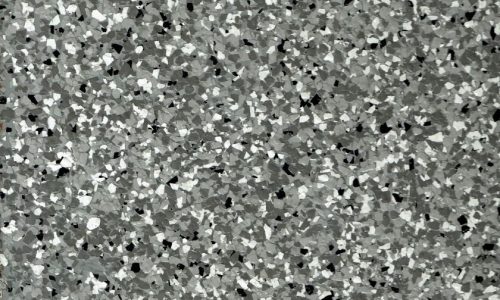

Multiple Color & Flake Color Options

Epoxy can be colored in a similar way that paint can be. We can make custom colors, and blend varying colors of flakes for unique finishes. Below are just a few common color options

More on Floor Prep for Epoxy Coatings

Diamond grinding is often a necessary preparation step for a successful epoxy floor application. Good prep work is essential for epoxy floor installations, failure to properly prep the floor can result in uneven finishes, cracks, bubbles, or failures in the coating. The below video shows one of our employees prepping a concrete floor with a diamond grinder, a close up is shown so you can see how the grinder creates an even but textured finish to the concrete. The ridges and grooves created by the grinder will serve to help bind the coating to the concrete permanently.

By clicking next or submit you agree to receive phone, email, or text communication from us per our Terms of Use and Privacy Policy. Message/data rates apply. We do not share information with third parties or marketing services. By submitting, you authorize Certa ProPainters to reach out via phone, email, or text for explicit information about project needs. We will never share your personal information with 3rd parties for marketing purposes or spam you. You can opt out at any time. Message/data rates apply. Consent is not a condition of purchase.